Agricultural Waste at the Service of ESG

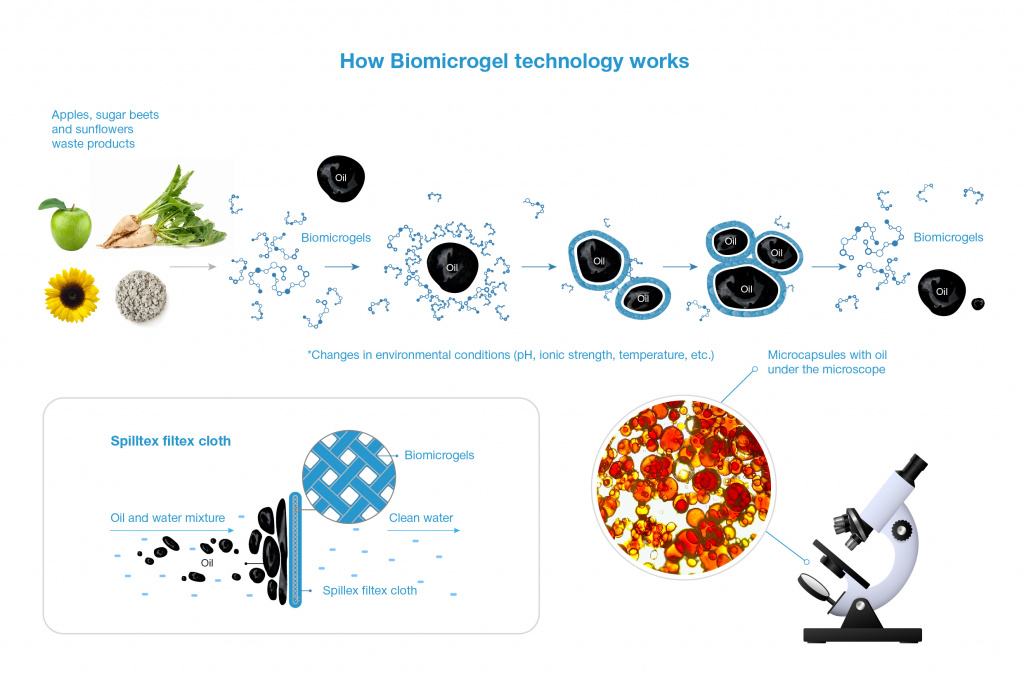

Unique biopolymers derived from apples, sugar beets and sunflowers create a new standard in water treatment and surface decontamination.

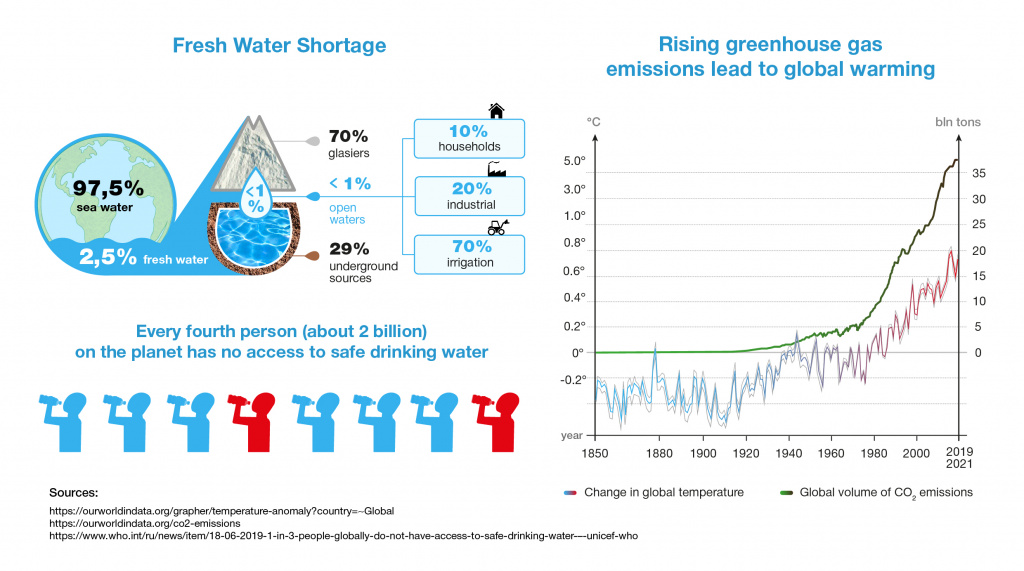

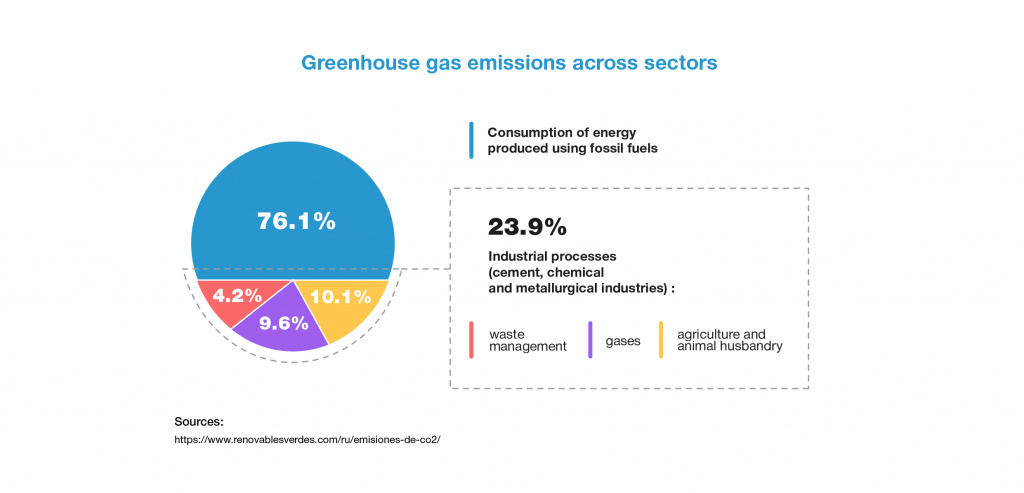

The problems of greenhouse effect and fresh water conservation are not new. However, in the 21st century humanity has come to a dangerous edge, when delays in solving these problems can lead to catastrophic consequences. More and more countries and companies are integrating the principles of environmental and social responsibility and corporate governance into their agenda. Compliance with ESG criteria improves reputation, increases competitiveness and boosts investment attractiveness. On the other hand, implementation of these criteria indeed helps reduce environmental and other risks that negatively affect society and our planet as a whole.

In light of this trend, requirements for processing and disposal of waste, improving the environmental safety of products, and introduction of "green" technologies are tightening all over the world. The main "allies" of mankind in this struggle are science and the high-tech solutions. Last year, during the G20 Innovation League conference, which was part of the October G20 summit and which was dedicated to technological developments that meet the global challenges of humanity, the G20 countries presented their cleantech solutions, and the technology from Biomicrogels Group was recognized as the best one. This new technology was made possible thanks to the joint effort of scientists specializing in biopolymer chemistry. It allows to bring industrial waste disposal to the whole new level through deep processing of agricultural waste – one of the biggest causes of fresh water pollution and greenhouse gas emissions.

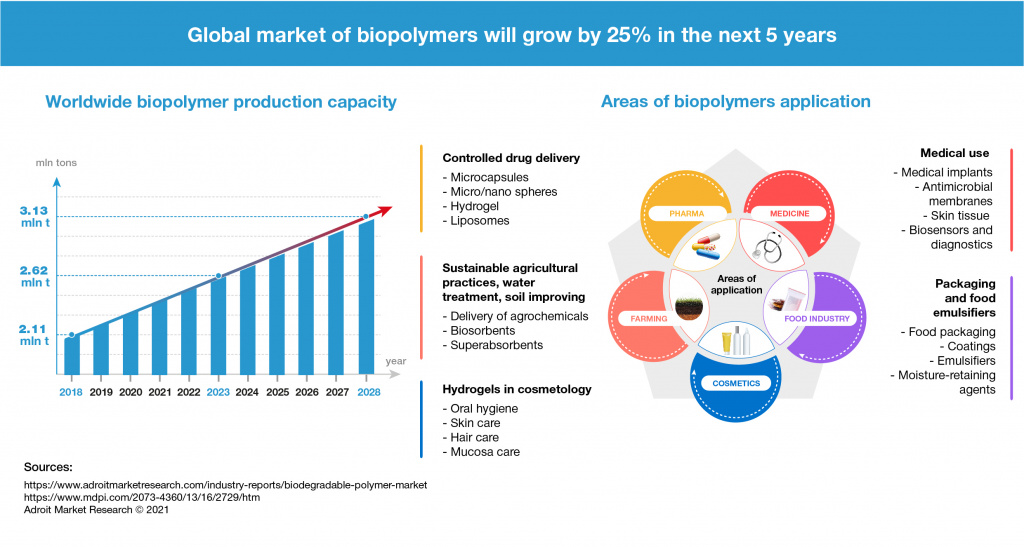

Biomicrogels are natural biopolymers and their advanced modifications that replace standard petroleum-based synthetic polymers used today in various human activities. Biomicrogels are already used to clean industrial wastewater from oils, fats and petroleum products, to process and dispose spent cutting fluids (cooling lubricants), in oil spill response, to increase the efficiency of vegetable oil extraction, and in the production of eco-friendly detergents and cosmetic products. They can purify water up to 10 times more efficiently than traditional solutions, reducing water and energy consumption, and decreasing overall waste and greenhouse gas emissions.

Biomicrogel technology uses a completely new principle – it encloses oils in microcapsules, separates them from the surface or water, and after separation, both oils and purified water can be returned to the technological cycle and reused. Biopolymers are fully biodegradable – within a day after applying, they decompose by 98%, and 100% biodegradation occurs in 3 days. The sludge resulting from the water treatment belongs to a safe waste class and can be easily disposed of.

Biomicrogels Group has made possible the use of biopolymers in new areas through utilizing the raw materials that are widely available throughout the world – the agricultural waste, including sugar beet pulp, apple pomace and sunflower baskets.

This technology has been actively used at many industrial enterprises in Russia and abroad. For example, the production cycle of one of the leading steel companies in Russia involves metal processing that requires cutting fluids. The content of oil products in the runoff of this plant can reach 2500 mg/dm3. The customer needed to reduce the residual concentration of oil products in the purified water to a level of less than 10 mg/dm3, with pH value ranging from 6.5 to 8.5. Another challenge was to minimize the sludge generated during the purification process. For coolant recycling, BMG-P7 coagulant was used in the form of a 2% aqueous solution. It binds emulsified drops of oils and petroleum products and separates them from water. The coagulant made it possible to separate the spent coolant, providing:

-

reduction of oil content in water from 2500 mg/dm3 to <1 mg/dm3;

-

pH value of the purified water within the range of 6.5-8.0;

-

no need to heat up coolant during purification;

-

when separating oil products, the technology allows to minimize wastes up to zero level;

-

volume of sludge of less than 2% of the volume of the spent coolant.

Another area of application for Biomicrogels is the treatment of industrial and storm sewage, formed at enterprises of many industries: metallurgy, oil production, oil refining, food, transport (railway, ports), etc. The enterprises are facing the following problems when treating wastewater: insufficient efficiency of existing technologies in separation of oils, fats and petroleum products (with residual content of such products at 30-60 mg/l and more, while the optimal level is 0.05-1 mg/l) and high capital and operating costs. The BMG-P2 coagulant and BMG-C2 flocculant effectively trap any mineral and vegetable oils, animal fats, as well as oil and oil products in water, reducing residual content down to 0.05-1 mg/l. After separation of the oil-water mixture, both purified water and extracted oil products can be returned to the technological cycle and reused.

One of the use cases of this technology in cleaning oil-containing industrial wastewater is locomotive depots, where water is being contaminated with oil products when washing trailing stock, as well as cleaning and steaming the railway tanks. Strict requirements are imposed on the quality of wastewater, and in case of their violation, the depot may incur additional costs – various fines for the negative environmental impact. SPC BioMicroGel offered their own solution based on the BMG-C2 flocculant, which made it possible to purify the wastewater generated at depots from oil products to the required standards.

As an example of using this technology in of oil spill response, in June-August 2020 SPC BioMicroGel took part in eliminating the impact of the environmental disaster in the Arctic, when more than 20 thousand tons of diesel fuel spilled in the vicinity of Norilsk. The two BioMicroGel products were used in that project: Spilltex filter material and BMG-P2 coagulant for water purification. These solutions demonstrated high cleaning efficiency, which was confirmed by an independent accredited laboratory and corresponding water sample tests. At the moment, the company is developing a separate line of equipment based on its Spilltex technology: filters and filtering systems for separating water-oil mixtures and purifying water from oils, fats and oil products, designed for the oil, food, transport and other industries.

Manufacturing detergents and cosmetics is yet another area where biopolymers have already started replacing standard petroleum-based synthetic polymers. Biomicrogels Group produces and sells its own line of environmentally friendly detergents and cosmetics based on BioMicroGel technology under its WONDER LAB, which are available in the largest retail chains and e-commerce platforms in Russia. The company has become the only Russian manufacturer in its product category to receive the European Ecolabel certificate. Also, WONDER LAB products have tested to be hypoallergenic. The company is preparing to bring the WONDER LAB consumer product line to the international market.

Biomicrogels Group has gone from a bold idea to an international company in less than 10 years. In 2012, while working on his doctoral thesis, Andrey Elagin (co-founder, CEO of Biomicrogels Group, CEO of SPC BioMicroGel) faced the problem of wastewater treatment from oils and oil products. At the same time, Maxim Mironov (R&D Director, PhD in Chemistry) was doing research on the development of microencapsulation technology and targeted drug delivery in humans. Having joined their forces, the team was the first in the world to transfer these unique modifications of biopolymers and the principle of microencapsulation from medicine to industrial environment and to apply them for safe and efficient purification of water and hard surfaces. Today, this technology is available to people in all spheres of life – from industry to domestic use, helping solve the global problems of the planet, such as the shortage of fresh water and the increase in greenhouse gas emissions.

This is how the Biomicrogels Group was born, which now includes 4 chemical laboratories, 2 production workshops and has more than 120 employees in 5 countries of the world. Today Biomicrogels Group technology is protected by more than 100 patents in 62 countries, including more 20+ countries in Europe, Russia, USA, Canada, India, China, Southeast Asia and the Persian Gulf. In total, the company’s estimated target markets exceed $250 billion.

The company intends to consolidate its success at the international level. The company’s current performance allows us to be confident in the feasibility of such plans. Gregory Berenstein, the international investor with 30 years of experience in the investment field, has recently joined the founding team, and the ex-president and country manager for GEA, Oliver Cescotti, has joined the company's board of directors. The company’s revenue for the 4th quarter of 2021 increased by 4.6 times compared to the 4th quarter of 2020, with gross margin for that period reaching 5.5 percentage points. In the next three years, the company is aiming for an IPO in the NASDAQ international stock exchange.

Source: https://expert.ru/2022/01/19/selkhozotkhody-na-sluzhbe-esg/</