The Report on Reduction of СО2 Emissions During Disposal of Waste Cutting Fluids with Biomicrogels® Demulsifier Was Recognized as the Best at International Conference WCWM 2022

Andrey Kryazhov, Senior Research Fellow at SPC BioMicroGel, shared his experience in reducing СО2 emissions with the Biomicrogel® demulsifier when disposing of spent cutting fluids (cooling lubricants) and presented the Biomicrogel® technology to leading scientists and industry leaders from all over the world at the 3rd World Conference on Waste Management 2022.

Andrey Kryazhov, Senior Research Fellow at SPC BioMicroGel, shared his experience in reducing СО2 emissions with the Biomicrogel® demulsifier when disposing of spent cutting fluids (cooling lubricants) and presented the Biomicrogel® technology to leading scientists and industry leaders from all over the world at the 3rd World Conference on Waste Management 2022.

The participants of this event, which has become the leading international platform for exchanging experience and presenting advanced developments in the field of waste management, recognized the cutting fluid treatment solution based on Biomicrogels® technology as one of the best.

At the event, experts paid special attention to the treatment of industrial and storm wastewater, which largely pollute the environment due to the high content of oil products, aldehydes, resins, phenols and other harmful substances.

This is especially important for metallurgy and mechanical engineering, since when treating wastewater, enterprises in these industries are faced with the problem of processing and disposal of spent metalworking fluids, which are basically a stable emulsion of oils in combination with stabilizers based on surface-active substances (surfactants) and biocides. The situation is further complicated by the fact that each year the industry generates about 20 million tons of spent fluids[1].

The number of methods for cleaning and recycling metalworking fluids is very limited, and most of them do not meet modern requirements both in terms of cleaning quality and cost. Physical methods, such as evaporation, are not very efficient and are quite expensive, as they consume a lot of energy, while chemical methods require significant amounts of reagents. In both cases, it is still necessary to dispose of sludge that contains oil products and surfactants. The volume of these wastes is usually at least 5% of the initial volume of the metalworking fluid, and their disposal by incineration leads to emissions of about 3 tons of carbon dioxide for every ton of waste.

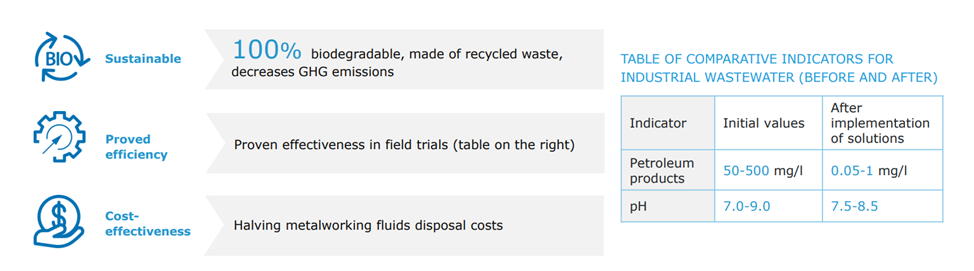

That is why it necessary to introduce advanced and environmentally friendly technologies for industrial wastewater treatment, recycling and processing of metalworking fluids in industries around the world. For example, the Biomicrogels® technology, which uses agricultural wastes and secondary products of agricultural processing as raw materials, makes it possible to purify the water separated during the treatment of cutting fluids to meet MPC standards, decreasing the amount of waste for disposal / dumping by 80%, reducing the processing cost by 2-3 times compared to traditional methods, while also reducing CO2 emissions.

Biomicrogels® reagents are carbon-neutral, since they are produced using agricultural waste as a raw material, which eliminates the composting of these wastes, and they do not require heating, which reduces energy costs. Biomicrogels® represent small particles of polysaccharide gels of a submicron size that concentrate at the interfaces between water and oil under the influence of thermodynamic forces. Biomicrogels® attach to oil droplets and disrupt the stability of the emulsion.

Biomicrogels® reduce the dosage of coagulants used in the disposal of waste metalworking fluids to 200 mg, and also allow to extract oils from waste, eliminating their subsequent incineration with the release of carbon dioxide. Each kilogram of Biomicrogels® reduces greenhouse gas emissions by 600–1500 kg of СО2-eq. during utilization of cutting fluids within its life cycle. When treating industrial and storm water to remove oils and petroleum products, Biomicrogel® solutions can be easily integrated into existing production lines, cutting down residual oil content in treated water to <1 mg/l and reducing waste volumes for landfill / disposal.

This solution has been actively used at many industrial enterprises in Russia and abroad. For example, one of the leading steel companies in Russia uses it in its production cycle, which involves processing waste metalworking coolants with the content of oil products potentially reaching 2500 mg/l. The customer required that the solution should reduce residual concentration of oil products in the purified water to a level of less than 10 mg/l, and the pH level should be in the range of 6.5-8.5. Another challenge was to minimize the sludge produced during waste treatment. For coolant processing, the Biomicrogels® BMG-P7 demulsifier was used, which is applied in the form of a 10% aqueous solution that binds emulsified drops of oils and petroleum products, separating them from water. The use of BMG-P7 demulsifier allowed to carry out the separation of spent metalworking fluids, providing:

-

reduction of oil content in water from 2500 mg/l to <1 mg/l

-

pH value of purified water in the range of 6.5-8.0

-

eliminating the need to heat the medium during the cleaning process

-

the proportion of sediment of less than 2% of the volume of the processed metalworking fluid

Thus, NPO BioMicroGeli represents an efficient and environmentally friendly technology for disposal of cutting fluids.

[1] С. Сheng et all Treatment of spent metalworking fluids. Water research (2005), V. 39, P. 4051-4063