Head of BIOMICROGELS GROUP: Green production is economic fundamental

The climate agenda has increasingly come to fore, attracting public attention, becoming a part of the economic life and being featured on the front pages of the world's leading media. For example, we may recall the mixed results of the COP 26 summit that ended a few weeks ago in Glasgow and the hype surrounding it.

The main sources of carbon dioxide emissions into the atmosphere are manufacturing production, transportation, processing and consumption of fossil fuels (86%), deforestation and biomass burning (12%), and other sources (2%).

There is no clear solution to this problem. However, the participants of the Glasgow climate conference confirmed that the global goal remains the same: in 2050, the temperature on the planet should not rise by more than 1.5 degrees compared to the end of the 19th century. This is the only way to avoid a climate catastrophe in the second half of the century.

Achieving this goal is not an easy task: in order for the global energy sector to reach zero emissions of greenhouse gases (primarily carbon dioxide and methane) by 2050, it will have to be completely rebuilt. The main hope here is that technology upgrade would help these efforts. In this regard, the BIOMICROGELS GROUP, which has developed a unique technology for reducing greenhouse gas emissions and preserving fresh water, has something new to offer its partners. Here are just a couple of examples: thanks to our reagents one of the largest metallurgical productions not only in the Russian Federation, but also in Europe, was able to improve its environmental posture (in the disposal of used cutting fluid) by more than 2 times. The solutions implemented by BIOMICROGELS GROUP at metallurgical plants allow reducing total CO2 emissions in steel production by 1-2%. At first glance, this is not that much, but if you take into account the processing of cutting fluids (cooling lubricants), this results in impressive 28-fold cumulative carbon footprint reduction.

What can make industrial production greener?

The answer to global climate challenges is ESG – these are the tracks that help companies ensure sustainable development. The ESG agenda that has arisen in the West is gradually beginning to dictate its own rules for the increasing number of Russian companies – otherwise they risk being left out of the global economy.

In the EU, five sectors have been selected for further tightening the carbon legislation. These are production, transmission and distribution of electricity; production of cement, lime and plaster; production of iron, steel and ferroalloys; production of basic chemicals and fertilizers; as well as extraction of crude oil. In the US, which is the world's second largest CO2 emitter after China, research suggests that the main focus in managing greenhouse gas emissions should be paid to energy, transportation, mining and heavy industries.

In the Russian Federation, the state control is just beginning – Russia started to develop its carbon legislation later than other countries. However, some trends can already be identified that are shaping the low-carbon industrial future. These include the following factors: technologies are being used to reduce the carbon footprint of the coal-based power generation; there is an active digitalization in many sectors of the economy; metallurgy and chemical industry are introducing hydrogen technologies; the country is developing steam-gas generation, nuclear power plants, hydroelectric power plants and renewable energy sources. In communal services and housing construction industries, it is planned to increase the efficiency of heat supply, improve HVAC systems and introduce energy-efficiency standards for new buildings. In agriculture, approaches to soil fertilization are being optimized (including the use of fertilizers with a slow release of nitrogen), with focus on "precision" farming.

Those who do not want to follow the ESG agenda will have to pay, and pay a lot. It has been calculated, for example, that the EU's carbon tax, once levied at 100%, could cost Russia's iron, steel, aluminum, fertilizer, cement and electricity suppliers at least €1.1 billion a year.

This amount explains the desire of Russian business to get out of the European carbon tax. In this regard, it is worthy to note the consolidated position of the members of the bureau of the Russian Union of Industrialists and Entrepreneurs, who believe that this European tax is exclusively protectionist in its nature, and its main goal is to support the competitiveness of European manufacturers by pressing manufacturers from other countries.

The Technology of Three E: Eco-friendly, Economic, and Efficient

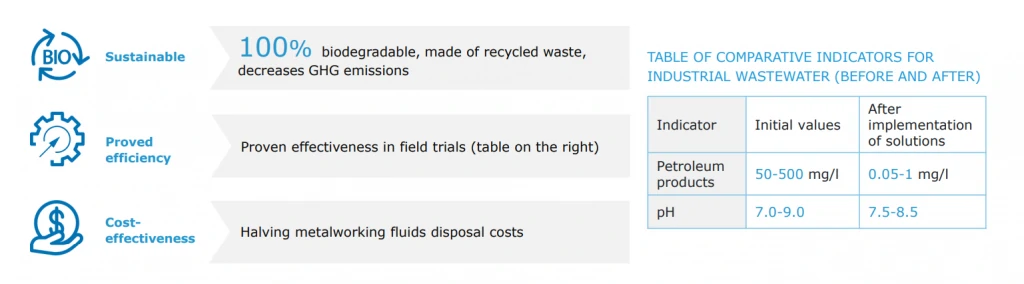

The industrial product line based on Biomicrogels® technology, which is widely used at Russian and foreign enterprises, helps to purify water up to 10 times more efficiently and economically than other similar solutions, while also optimizing the process in terms of energy costs and greenhouse gas emissions.

To better illustrate the environmental and economic feasibility of implementing our solutions, let’s see how Biomicrogels® reagents are helping the large metallurgical plant in the Russian Federation enhance its environmental posture. Metallurgic plants actively use cutting fluids in their production processes. After use, they lose their useful properties and need to be disposed of. This is not easy an easy task: the spent coolant is a stable emulsion that practically does not decompose naturally, therefore it is unacceptable to discharge it into water bodies and treatment facilities without prior neutralization and purification.

The rolling mill of our customer’s plant produces 40-50 cubic meters of spent coolant each day. To process and dispose of this waste, we proposed a solution based on our Biomicrogel® BMG-P2 coagulant, which effectively captures any mineral and vegetable oils and petroleum products contained in water. After separation of the oil-water mixture, purified water can be returned to the technological cycle and reused. The resulting precipitate is of Hazard Class 4 and can be easily degraded to completely harmless components.

The BioMicroGel BMG-P2 coagulant is used as a 2% aqueous working solution; it binds (encapsulates) emulsified droplets of oils and petroleum products and forms stable insoluble compounds. When further processing these compounds, a precipitate is formed, which is removed from the water by filtration or settling

The BioMicroGel BMG-P2 coagulant is used as a 2% aqueous working solution; it binds (encapsulates) emulsified droplets of oils and petroleum products and forms stable insoluble compounds. When further processing these compounds, a precipitate is formed, which is removed from the water by filtration or settling

It is also important that BMG-P2 is based on polysaccharides – it is obtained by complex processing of vegetable raw materials: sugar beet pulp and apple pomace. The biodegradable coagulant BMG-P2 is completely environmentally friendly and yet easily separates even the most persistent emulsions.

So, what is the result? We managed to reduce the concentration of oil products, not only meeting the requirements specified by the customer, but exceeding this figure by 50 times. The volume of waste transferred for disposal has decreased 5 times compared to alternative methods of sorption treatment.

Formation of a fully recyclable sludge eliminates waste disposal, and, combined with a five-fold reduction in waste volumes, leads to a significant reduction in the negative environmental impact and a decrease in the carbon footprint in comparison with the sorption treatment technology. In general, implementing a solution based on BMG-P2 in some cases turned out to be twice as profitable as alternative options or the disposal of used cutting fluids by third-party companies.

Through our other projects we have demonstrated that the use of Biomicrogels® technology in processing spent cutting fluids results in the formation of final waste that is reduced in volume by up to 200 times, and, which is more important, is in a solid state. This greatly expands the possibilities for its further disposal and deactivation to completely safe components. Our technology allows companies whose activities are related to working with cutting fluids to significantly reduce their costs, related to fines that are charged as a result of exceeding residual oils and petroleum products in wastewater. It allows them to reduce the downtime of equipment that occurs as a result of its pollution with oils and petroleum products in the case of using insufficiently purified water in technological cycles. Besides, it reduces logistical costs that arise when they have to hand over a large amount of industrial waste, and allows them to switch to a safer and more cost-effective processing technology. Thus, companies that generate spent cutting fluids as industrial waste can recycle it themselves up to 2 times more profitable compared to commercial recycling at third-party companies. Meanwhile, waste processing companies now have an opportunity to take the leading position in the legal market, securing a competitive advantage in the disposal waste such as cutting fluids and other oil-in-water emulsions, and increasing their net profit by up to 50%.

Unfortunately, today there are still companies that discharge industrial waste into the environment without a sufficient degree of treatment or without treatment at all, but the enhancements in environmental legislation with simultaneous tightening enforcement efforts will help build the right demand in this market – a demand for technically proven and cost-effective solutions for the processing of industrial waste, that will allow companies to comply with regulations and at the same time earn money (in the case of companies that generate spend cutting fluid – save money), ensuring high business performance from both a financial and environmental point of view. BIOMICROGELS GROUP is ready to offer just such solutions.

List of references:

1) https://www.dw.com/ru/66-стран-обязались-достичь-углеродной-нейтральности-к-2050-году/a-50549076

2) https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&c...

3) https://rg.ru/2021/09/23/v-rossii-mogut-vvesti-uglerodnyj-nalog.html

4) https://www.diva-portal.org/smash/get/diva2:1076315/FULLTEXT01.pdf

5) https://www.rbc.ru/economics/26/07/2021/60fac8469a7947d1f4871b47

6) https://ec.europa.eu/info/sites/default/files/carbon_border_adjustment_mechanism_0.pdf

7) https://www.vedomosti.ru/management/articles/2021/02/25/859326-rossiiskie-kompanii

8) https://cyberleninka.ru/article/n/povyshenie-ekologichnosti-deyatelnosti-organizatsiy-za-schet-razvi...

9) http://www.consultant.ru/cons/cgi/online.cgi?req=doc&base=OTN&n=734#06485174793703775

10) https://trends.rbc.ru/trends/green/61965cf29a7947c8bf283846

11) https://ria.ru/20090922/185975866.html