New Biomicrogels®-Based СО2-Reducing Solutions for Oil Industry Have Been Presented at International Conference on Sustainability

Maxim Mironov, Doctor of Chemistry, the co-founder of BIOMICROGELS GROUP and main developer of Biomicrogels® technology, spoke at the International Conference on Sustainability: Developments and Innovations (ICSDI 2022) with a presentation on “Water purification from oil and petroleum products using solutions based on Biomicrogels® technology”.

The ISCD 2022 International Conference on Sustainability: Development and Innovations is an innovative conference hosted by the College of Engineering, Prince Sultan University on February 19-22, 2022 in Riyadh, Saudi Arabia. This year the event was dedicated to various aspects of the Sustainable Development Goals (SDGs). The conference speakers and participants, including representatives of Red Sea Development, AMAALA, Fraunhofer ISC, EXPRO, the American Society of Civil Engineers and UNDP (United Nations Development Program), shared their experiences and identified potential partnerships in the field of sustainable development.

Particular attention was paid to the track of production and industrial systems that support sustainable development, where Maxim Mironov dwelled in detail on reducing СО2 emissions in the oil industry when cleaning industrial and storm wastewater purification from oil and petroleum, responding to oil spills, as well as treatment of bottom sediment and produced water using solutions based on Biomicrogels® technology.

Biomicrogels® are biodegradable polymers obtained by deep processing of agricultural raw materials: apple and beet pulp. These new polymers can replace standard petroleum-based synthetic polymers in various fields of human activity. Biomicrogels® cover any oils drops contained in water with a film, forming microcapsules and quickly binding them together – in this form, oils can be easily separated from water, and, subsequently, both oil and water can be returned to the process. Thus, the companies can reuse their water resources. Biomicrogels®-based products and solutions help purify water up to 10 times more efficiently and cost-effectively than comparable solutions, while also optimizing energy consumption and reducing greenhouse gas emissions. Biopolymers are completely biodegradable – after use, they decompose in the natural environment by 98% within a day, and complete biodegradation occurs within 3 days. The sludge resulting from the water treatment process belongs to a safe waste class and can be easily disposed of.

All products and solutions based on Biomicrogels® technology are carbon neutral since they are produced from agricultural waste. During the production of Biomicrogels®, no additional CO2 emissions occur (zero emissions in Scope 1). Biomicrogels® are derived from agricultural waste, such as apple pulp, which mostly cannot be reused and is normally utilized by composting, resulting in a release of 1.1 kg of CO2-eq per 1 kg of pulp. By using such pulp as a raw material, the carbon footprint from the production of Biomicrogels® is minimized, which, taking into account energy commodity consumption (Scope 2) does not exceed 0.36 kg of CO2-eq. per 1 kg of product. The use of Biomicrogels®-based solutions in treating industrial wastewater from oils, fats and petroleum products, in processing and disposing of spent cutting fluids (cooling lubricants), in oil spill response and to increase the yield of vegetable oils production, makes it possible to reduce global CO2 emissions by up to 23 million tons per year.

As an example of using this technology in responding to oil spills, in June-August 2020 SPC BioMicroGel took part in eliminating the impact of the environmental disaster in the Arctic, when more than 20 thousand tons of diesel fuel spilled in the vicinity of Norilsk. The two BioMicroGel products were used in that project: Spilltex® filtering material and BioMicroGels® BMG-P2 coagulant for water purification. These solutions demonstrated high cleaning efficiency, which was confirmed by an independent accredited laboratory and corresponding water sample tests. At the moment, the company is developing a separate line of equipment based on Spilltex® technology: filters and filtering systems for separating water-oil mixtures and purifying water from oils, fats and petroleum products in the oil, food, transportation and other industries.

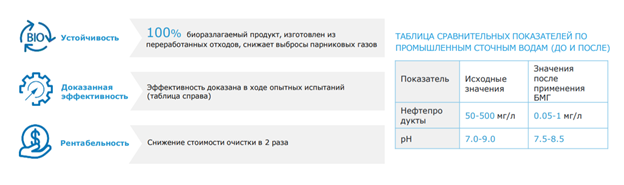

When cleaning industrial and storm water from oils and petroleum products, the enterprises most often face the following two problems: low efficiency of existing technologies for cleaning industrial wastewater from oil products (with residual content of such products at 30-60 mg/l and more, while the optimal level is 0.05-1 mg/l) and high capital and operating costs of existing technologies for treating oily waters, including the cost of reagents. The Biomicrogel® BMG-P2 solution is built into the existing line of equipment and allows companies to reduce oil products in their wastewater to values below 1 mg/l, thus, reducing the volume of waste for disposal.

Often, during the treatment of bottom sediment and produced water, the following problems arise: low efficiency of the existing technologies for treating bottom water and associated produced water from oil products (with residues of 50-60 mg/l, while the optimal level is 10-20 mg/l); high capital and operating costs of the existing treatment technologies for oily waters and separating water-oil emulsions; negative impact of oil and gas facilities on the environment. The solution based on Biomicrogel® BMG-P2 allows industrial enterprises to purify water to a final oil content of 4-10 mg per liter.

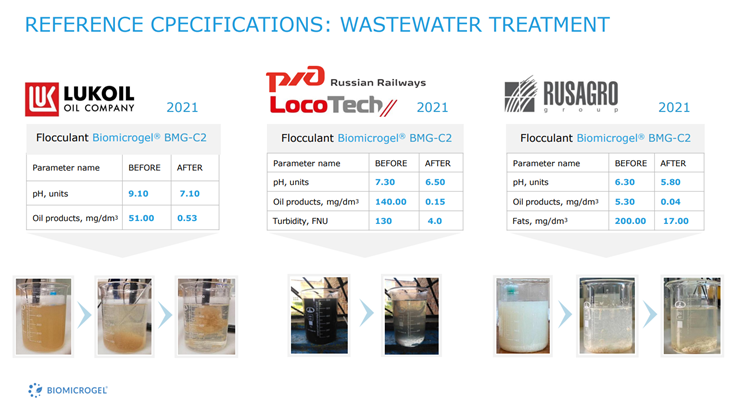

The Biomicrogels® technology has been successfully tested in pilot tests at such enterprises as LUKOIL, Russian Railways, Rusagro and many others.

ABOUT BIOMICROGELS GROUP

The Biomicrogels Group is an international fast-growing technology group of companies founded in 2012 by a team of engineers who created the groundbreaking Biomicrogels® technology aimed at solving global problems of saving fresh water and reducing greenhouse gas emissions.

Biomicrogels® are natural biopolymers and their advanced modifications that replace the standard petroleum-based synthetic polymers used today in a wide variety of human activities.

Based on its patented Biomicrogels® technology, the group has created a product line of biodegradable coagulants, flocculants, demulsifiers, filtering materials and offers turnkey solutions for industrial wastewater treatment from oils, fats and petroleum products, for processing of used cutting fluids in mechanical engineering and metallurgy, to increase the efficiency of vegetable oil recovery in the food industry, as well as for oil spill response. The company’s products help purify water up to 10 times more efficiently and economically than comparable solutions, while optimizing energy costs and reducing greenhouse gas emissions.

The Biomicrogels Group includes 4 chemical laboratories, 2 production workshops and more than 120 employees in 5 countries around the world. Today Biomicrogels Group technology is protected by more than 100 patents in 62 countries, including more than 20 countries in Europe, Russia, USA, Canada, India, China, Southeast Asia and the Persian Gulf. In 2021, G20 members, global experts and investors recognized the high-tech Biomicrogel®-solutions as the best in the Cleantech category among the most innovative companies representing the G20 countries.