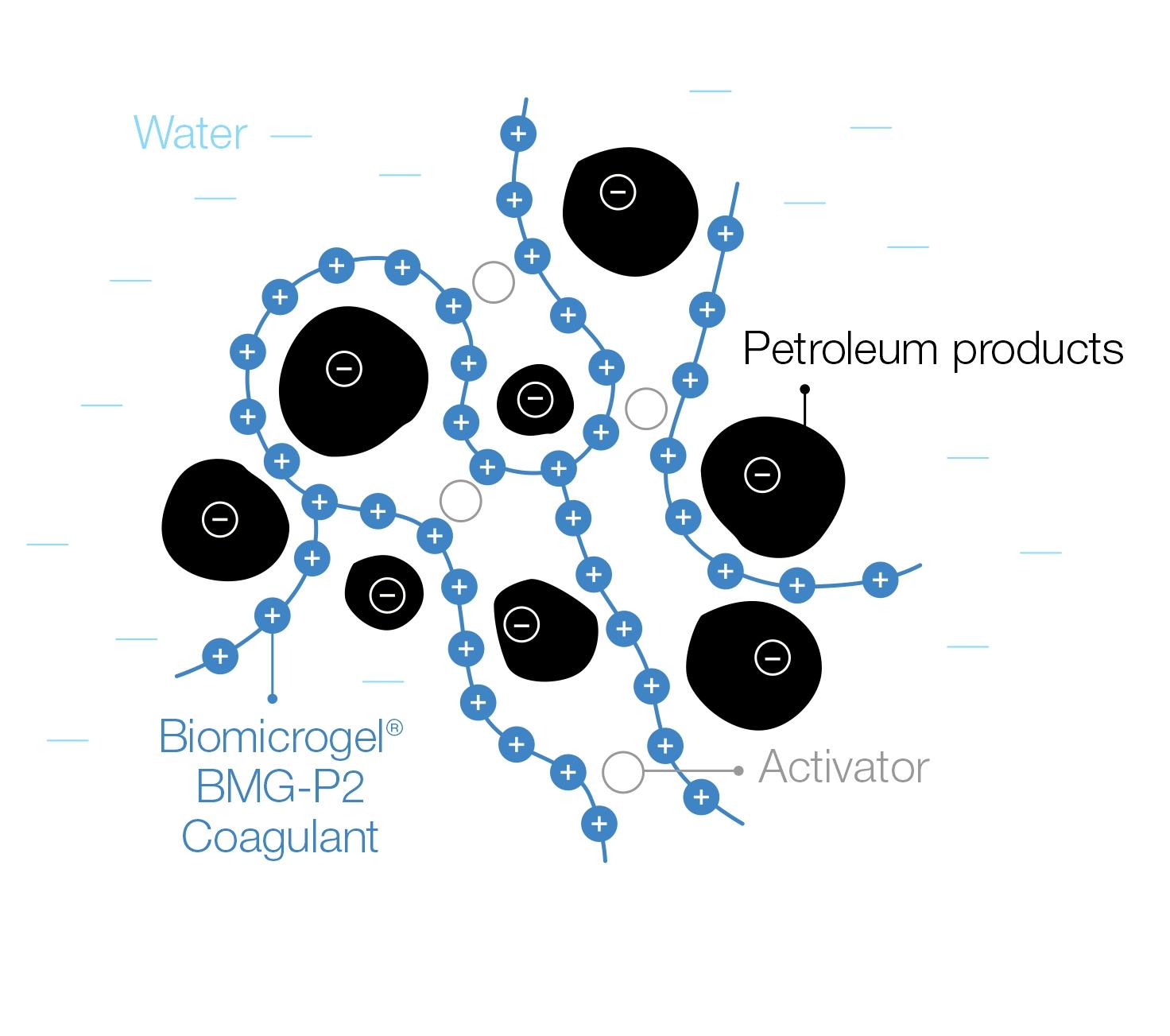

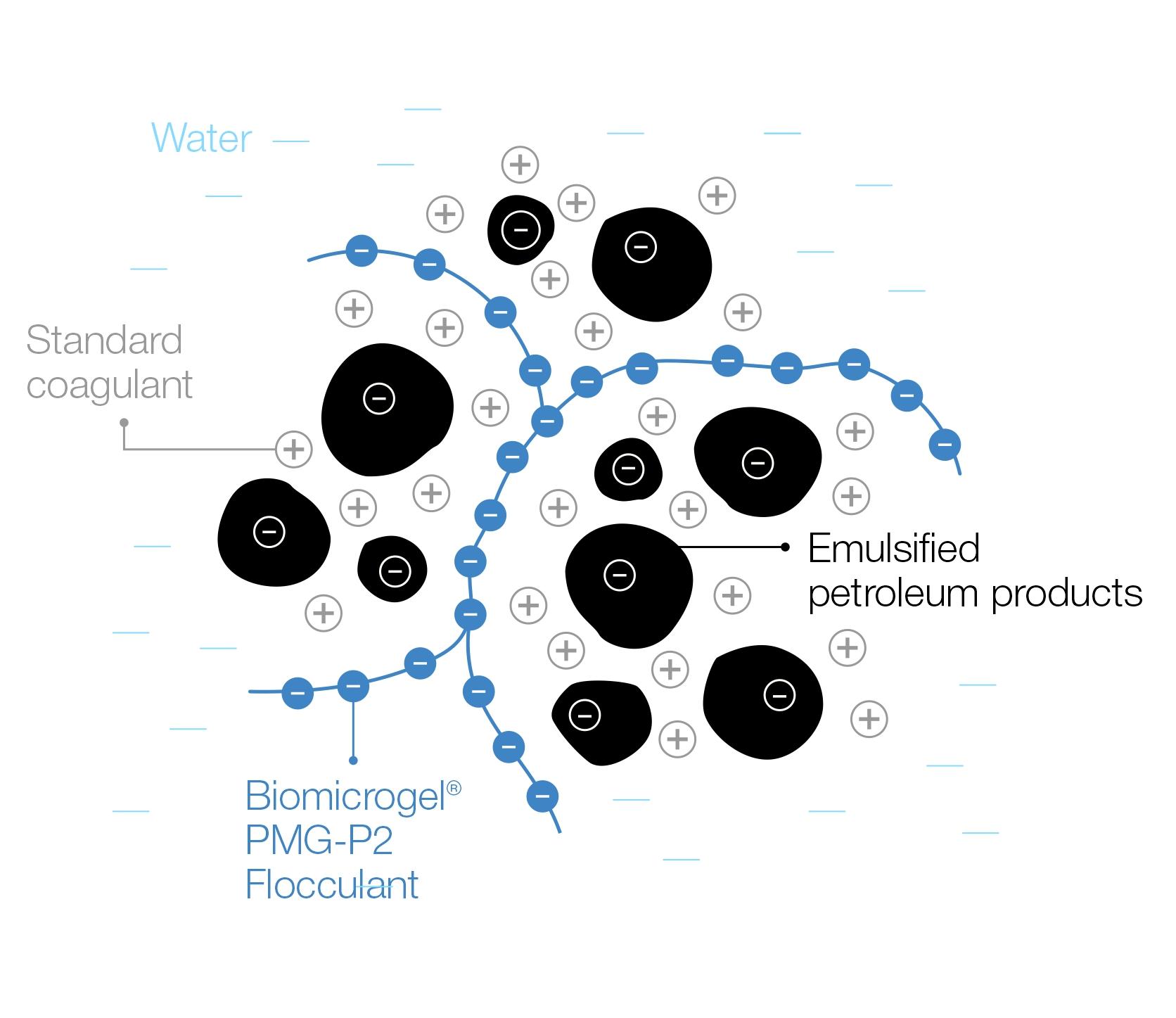

Biomicrogel® BMG-P2 flocculants separate even the most resistant (stable) oil-in-water emulsions, effectively catching any mineral and vegetable oils, animal fats, and oil and petroleum products in water effectively, based on a sweep-coagulation process. After the separation of the oil-water mixture both the treated water and removed petroleum products can be returned to the process cycle and re-used. Biomicrogel® BMG-P2 flocculants are highly compatible with almost all flocculants based on inorganic salts of polyvalent metals that are used cleaning water from suspended particles.

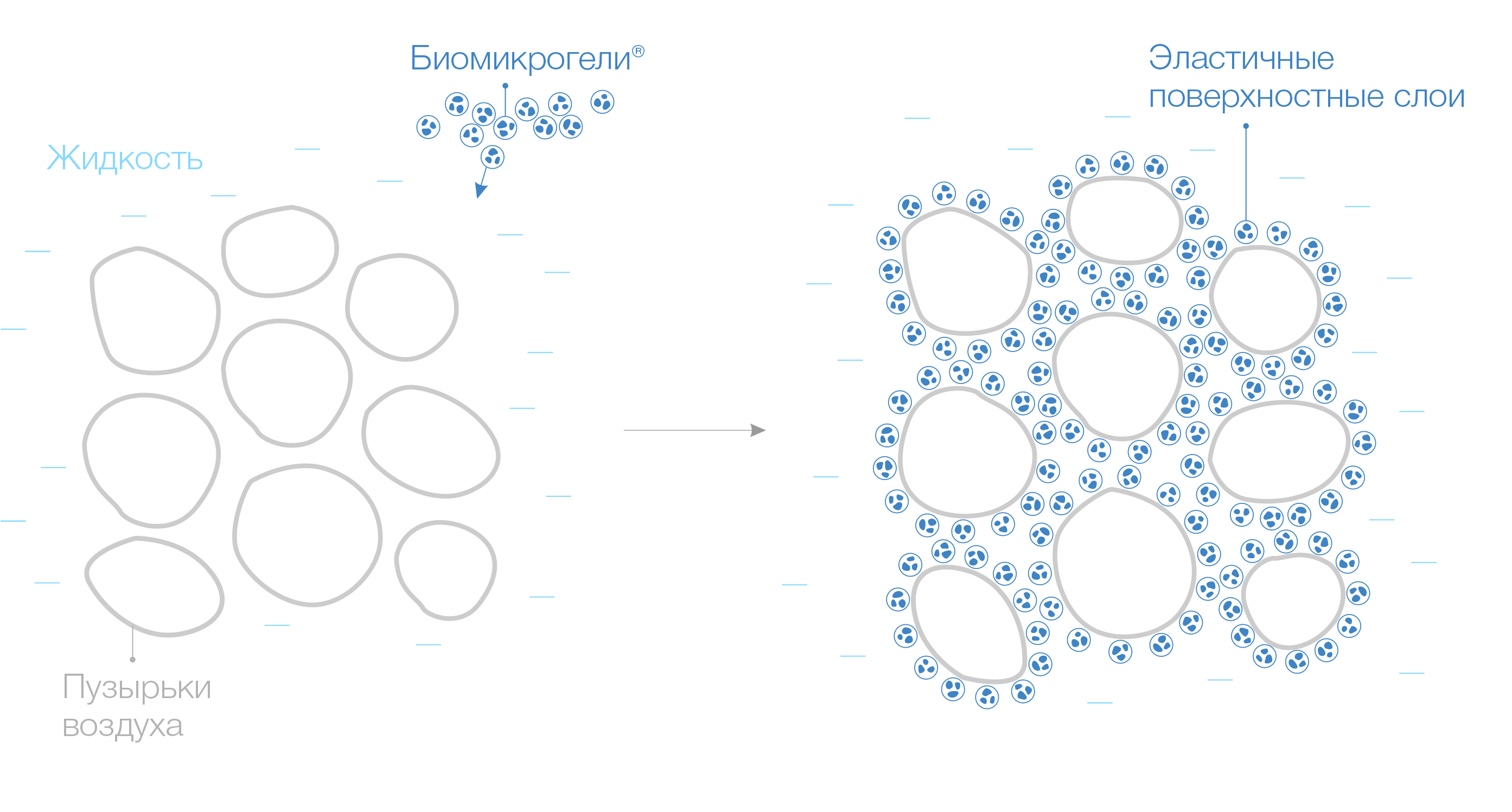

The sorbent activity of Biomicrogel® BMG-P1 is based on the same concept. Upon contact with any lubricants, oil, or petroleum products in saline water, it immediately forms a submicron polymer film at the oil–water interface, forming microcapsules with these pollutants contained inside. After that the microcapsules merge with each other turning the source petroleum product into a viscous jelly which is much easier to collect from the water surface. In this form the petroleum products do not spread out over long distances (the oil spill area can be reduced by up to 50 times), it does not stick to other surfaces (plants, birds, fishes, mammals, equipment, rocks etc.), and doesn’t catch fire or promote burning. Afterwards, the petroleum products can be returned to the process cycle after their removal.

Download the diagram

Biomicrogel® BMG-C2 flocculants for the treatment of water are high-molecular polymer compounds acting as molecular links designed for merging the smaller particles of pollutants into bigger and sustainable floccules (agglomerates), which easily settle/float upwards and are easily phyiscally separated from the water. Biomicrogel® BMG-C2 flocculants are highly compatible with almost all flocculants based on inorganic salts of polyvalent metals. You can see how it works in the diagram.

Download the diagram

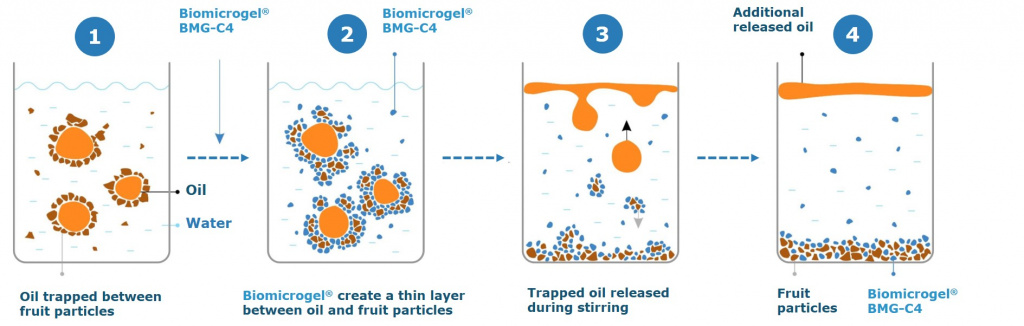

Biomicrogel® BMG-C4, which is used to increase the efficiency of the extraction of vegetable oils during the process of their production, has the ability to separate oils from solid particles. After crushing/pressing the fruits/seeds of vegetable oil crops during the process of oil extraction in the aqueous phase, as well as during the stages of settling and centrifugation, the goal is to maximize the separation of the oil sandwiched between the particles of the crushed culture. Biomicrogel® BMG-C4 can be used at each of those stages. Upon contact with drops of oil in the aqueous phase, Biomicrogel® BMG-C4 stabilizes at the oil-water interface forming submicron polymer films, displacing the drops of oil from the particles of the crushed crop, after which they rise to the surface.

Unlike the other Biomicrogel® modifications used as a sorbent, flocculant, or flocculating agent where the strength of films (microcapsules) is critical and must be maintained for a long time, in this case it is only necessary to ensure their short-term presence on the surface of the solid particles, ensuring the oil is separated from the solids and rises to the surface of the water. After the process is completed, Biomicrogel® BMG-C4 is distributed in the aqueous phase and over solids.

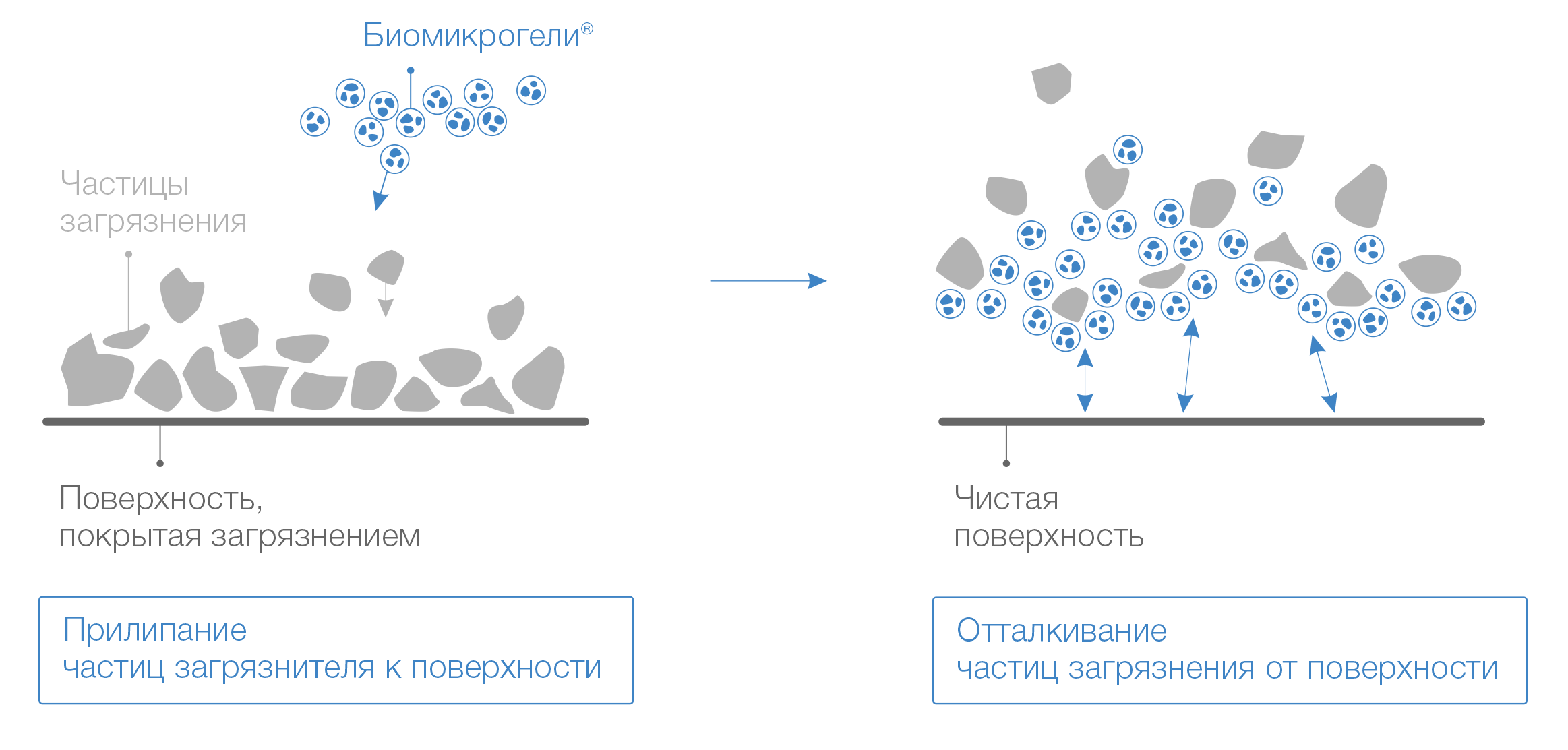

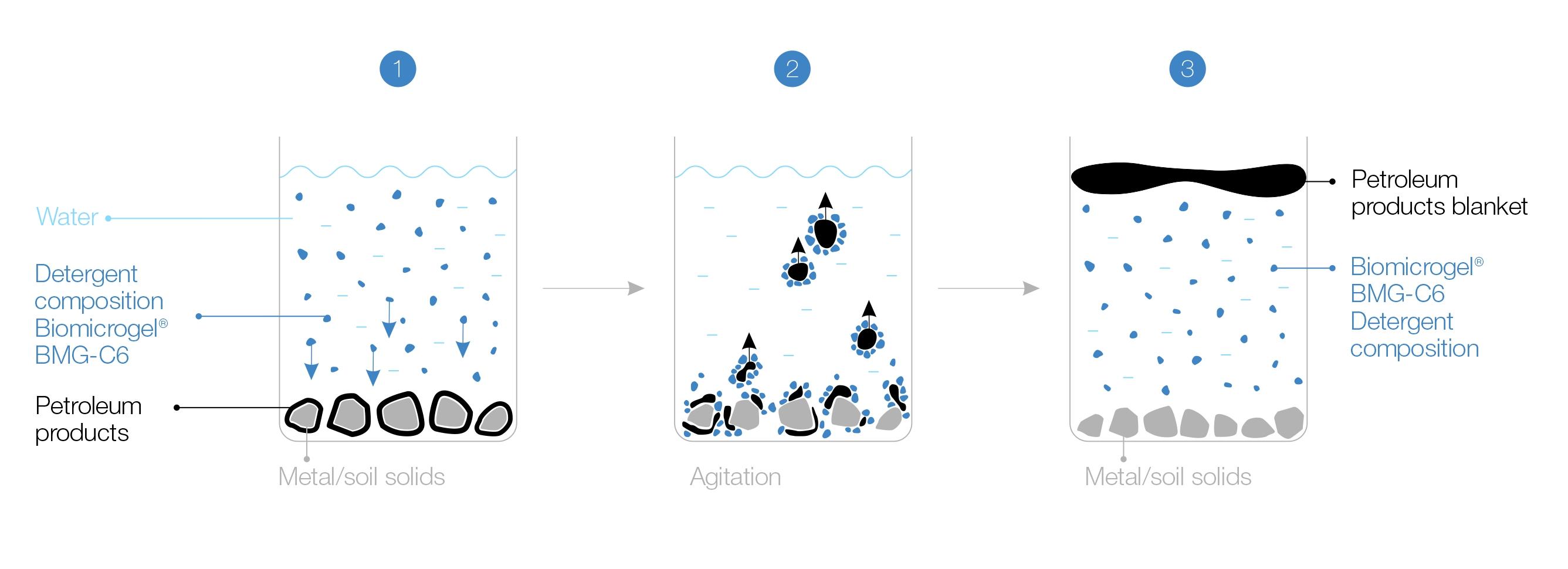

Biomicrogel® BMG-С6 is used to clean hard surfaces and has the ability to separate oils, greases, and petroleum products from solids (metal swarf, scale). Upon contact with solids contaminated with oil, Biomicrogel® BMG-С6 forms an extremely thin film between the solids and oil, thereby separating the pollutant from the surface of the solids.

Therefore, Biomicrogel® BMG-С6 makes the removal of any oil, grease, or petroleum products from solids highly effective. The cleaning process can be intensified by supplementary mixing or heating. The Biomicrogel® BMG-С3 soil cleaning reagent works in a similar way.

SPILLTEX®

Therefore, we produce Spilltex® membranes that are used for the fabrication of filters of any capacity and for the containment of emergency oil spills. These are in the form of resistant barriers for shallow rivers and streams, for gathering petroleum products from the water’s surface (scooping nets, oil skimmers), and also for protection of land and soils against pollution with petroleum products (protective meshes for coastal areas, sumps, and soils).